August 7, 2024 – Ubud, Bali.

On my last day in Bali I was fortunate enough to meet master papermaker Naruse Kiyoshi. Originally from Japan, Naruse came to Bali in 1992 as a freelance editor to write about local Balinese fishermen and their exports of tuna to Japan. This was the beginning of lifelong love affair with the island, settling there in 1995. It was in Bali in 1998, when he first learned about the method of making banana paper from a friend who attended a workshop in Australia. He started to experiment with the technique and established his studio in 2002 to dedicate to his research. Soon after, Naruse became known for his expertise in papermaking and was invited to teach workshops abroad, including one in Brisbane in 2011.

A commitment to passing on his knowledge to Balinese artists has been of primary importance to Naruse’s practice. His studio has a team of eight Balinese staff who complete each step of the process by hand. He admires how Balinese have a collaborative work ethic, in contrast to the Japanese who tend to prefer to work individually. Naruse proudly pointed out his successor, who has been trained to run the studio when he is no longer able to.

This team allows Naruse to work at the scale in which he does and to pursue his research into developing different shapes, textures, colours and uses for the paper. In his showroom, there are a selection of his wall hangings, lamp shades, screens, and coffee tables on display. At the opening of a recent exhibition in Bali showcasing his work, he wore a complete outfit made from his paper. The versatility of this paper has made it much sought after by interior designers and architects from across the region.

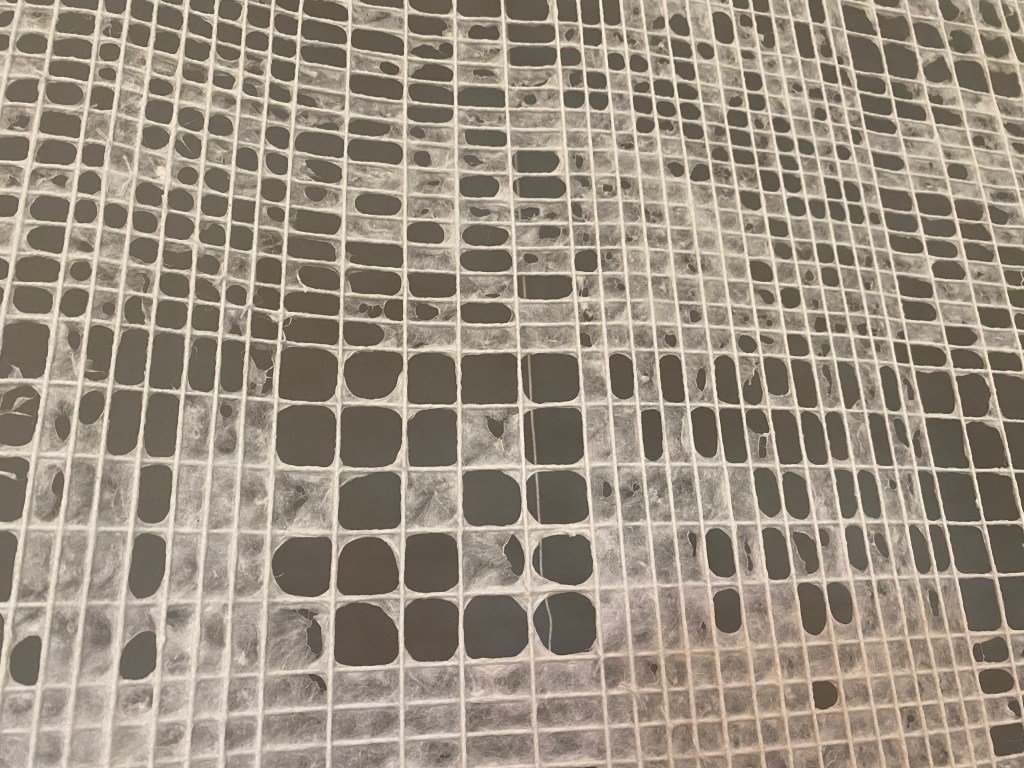

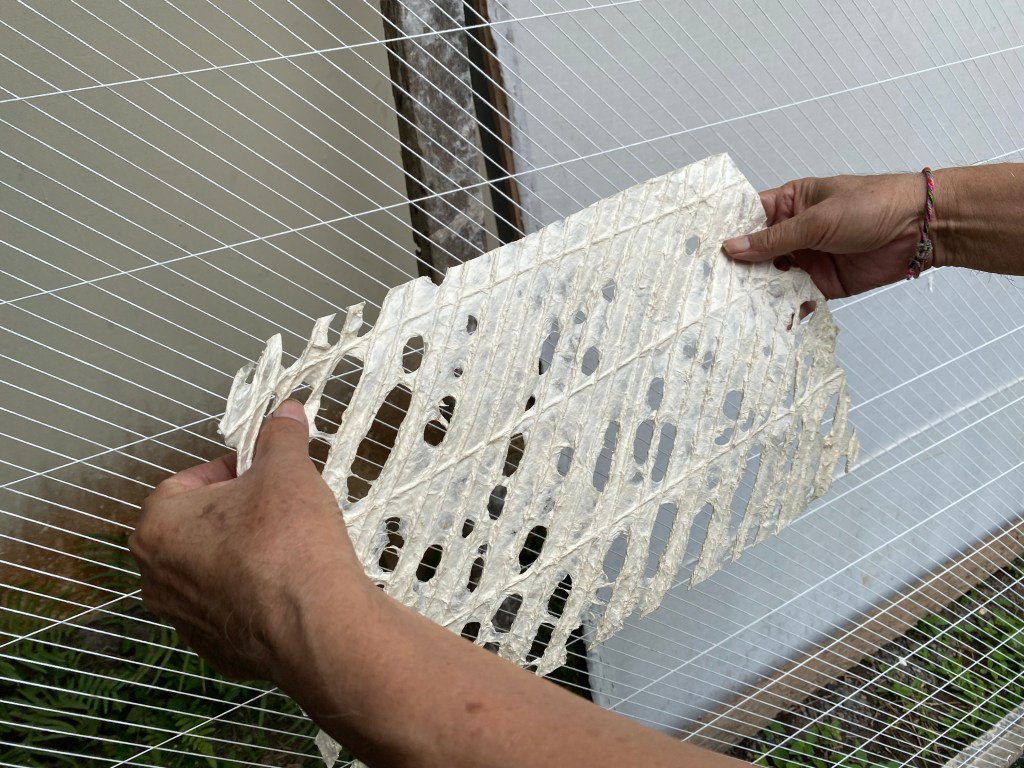

After mastering the technique in making banana paper, Naruse’s aim was to see how he could push the medium to create different textures. This led him to develop a technique where he produces a grid of geometric lines using thin string attached to a wooden frame, on top of which he applies the pulp in varying consistencies resulting in organic patterns as the pulp attaches and dries.

Some of this paper is thin and soft, resembling fabric, which can then be dyed. Naruse has several natural dyes he uses to make various colours. One is a bright orange-red, made from the seeds found in the spikey red pods of the “lipstick tree” that grows in his studio. He uses other natural materials including turmeric and indigo, some of which he grows himself or sources from across Indonesia.

Banana stalks are an ideal material for papermaking as they release a natural glue when processed that acts as a binder for the paper, giving it the same strength and durability as Japanese Washi paper. He has found that pineapple leaves and the soft pith inside the skin of the durian fruit also release the same glue.

At the entrance of his studio is a large pile of banana stalks. He shows us how the stringy exterior of the stalk is removed exposing the smooth core underneath which is then cut into shorter lengths, of roughly 60cm, for processing. The core is made up of rings that can be peeled off by hand and broken down into thin strips.

These strips are then cut into smaller pieces of roughly 5cm by 3cm to be boiled in large cast iron pots until broken down. Caustic soda is added to aid the process of breaking down the fibres and bleach will be used if he wants the paper be white, otherwise the result is between a creamy yellow and tan.

The screens he uses to pull a sheet of paper are 3 meters by 2 meters which are submerged into a shallow, purpose-build water bath. The pulp is then applied on top of the screen once it is submerged in the water and a team of three people evenly dispersed the pulp across the screen by hand. When finished, the screens are placed upright to dry in the sun before being peeled off, rolled up and stored away.

His studio is worth a visit to any aspiring papermakers, lovers of handmade paper and working by hand with natural materials. You’ll need to make an appointment and, unfortunately, Naruse doesn’t currently offer workshops which means you’ll need to simply soak up the experience to inspire your future paper making projects.