August 4, 2024 – Ubud, Bali.

As a printmaker, I’ve always had a fascination with paper, in particular handmade paper from natural materials. To learn more about papermaking in Bali, I attended a workshop at Usaha Daluang Kreatif, a papermaking studio in Ubud, established by Aryatama Nugraha in 2023. As the son of a printmaker, Devy Ferdianto, he was interested in researching how to make paper locally and had established the studio to experiment with new and old printmaking technologies, using local materials to create an internationally recognised Indonesian handmade paper.

Daluang is the name of the variety of Mulberry tree that is found in Indonesia. It most closely resembles the Japanese Kozo variety and was brought from China through the Silk Road trade routes during the 15thCentury. Daluang was, and still is, used for ceremonial purposes, to write religious scriptures in the Hindu, Islamic and Buddhist traditions. Mantras are also written on small squares of Daluang, along with the names of deceased family members, which are ceremonially burned with the body.

In contrast to Daluang, which is a bast fibre, Abaca is closer to banana fibre, which was introduced to Indonesia via the Philippines by the Dutch sometime between the first and second world war. Abaca is often referred to as Pilipino hemp and was used for weaving and clothing. Breadfruit was also used like the Mulberry tree to make bark cloth and made into clothing. The tools used to beat the bark into cloth is a brass and natural fibre tool introduced by the Dutch, that is still used today. Aryatama experiments with each of these materials, individually and in combination.

The process for preparing the Daluang starts by harvesting the plant when the stem is one to two centimetres in diameter. The younger the plant, the whiter the fibre and easier to process. The stems are soaked until soft enough to remove the outer bark by hand. The surface of the bark that has been removed is then scraped off and left to soak again overnight to soften further. The bark is then placed into a pot with caustic soda to boil for two to three hours until the bark starts to release a natural glue.

After removing the fibre from the pot, it should be soft enough to mould into a ball in the palm of your hands. It is then placed onto a wooden board and beaten with a mulberry stick, three to four times, flipping it over between each beating. At this point it can be stored in a fridge or freezer to be used as needed.

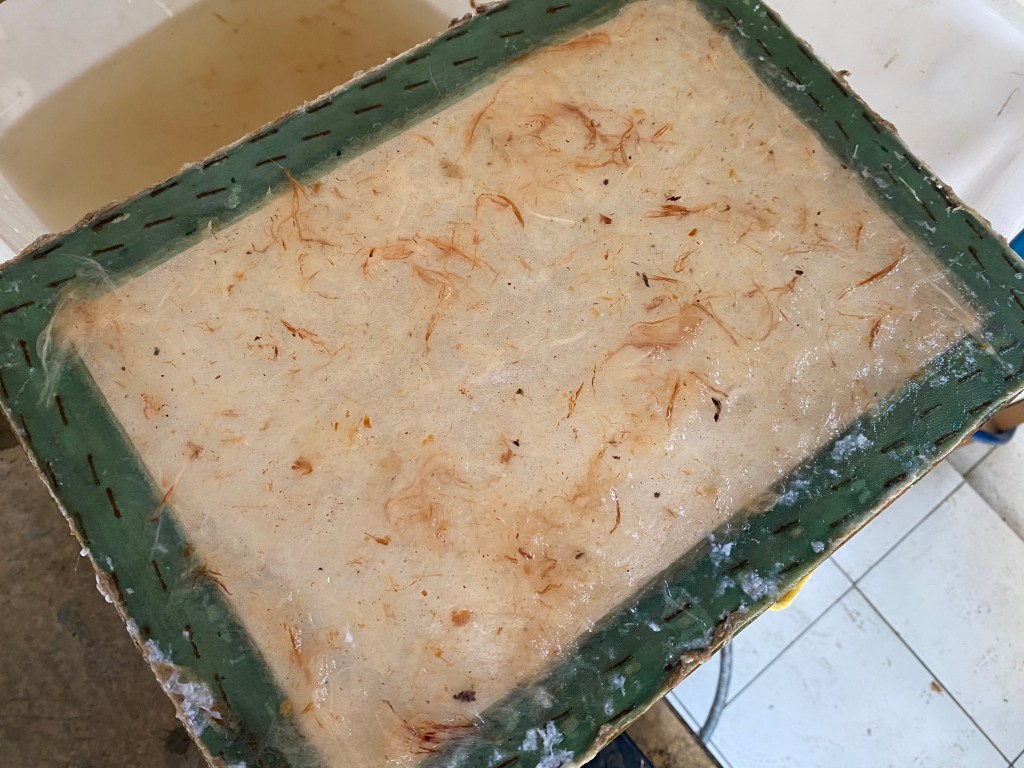

A sheet of paper can be made by adding the hand beaten pulp to a tub of water, sometimes combining this with a finer pulp made in an electric blender. The mould and deckle is dipped into the tub at a 45 degree angle, repeating one or two times if necessary to get the desired thickness.

To dry the paper, the mould is placed face down onto a large screen (the same that is used for silk-screen printing) and an absorbent cloth is pressed on the back of the mould to remove enough water until the mould can be carefully lifted without taking the pulp with it. The sheets can then take a few days to fully dry depending on the weather.

Aryatama is passionate about sharing this research with artists and offers workshops as well as residencies at his studio. Please get in touch if you are interested in learning more about his research or doing a residency. @usaha_daluang_kreatif